Boost Your Output, Squarely.

The Ultimate Guide to Welding Square Tube Forming Machines

In the world of metal fabrication and construction, square and rectangular tubes are indispensable. From structural frameworks and furniture to industrial machinery and architectural designs, their clean lines and high strength-to-weight ratio make them a top choice. But have you ever stopped to wonder how these perfectly formed tubes are made efficiently and consistently?

The answer lies in a powerhouse of modern manufacturing: the Welding Square Tube Forming Machine.

At its core, a square tube forming machine is a continuous roll forming system designed to transform a flat metal coil (typically mild steel, stainless steel, or aluminum) into a perfectly shaped square or rectangular tube. The process is fully automated, integrating forming, welding, and sizing into one seamless, high-speed production line.

These machines have revolutionized tube production, replacing slower, more labor-intensive methods and ensuring unparalleled consistency and quality.

The journey from a flat strip to a finished tube is a fascinating feat of engineering. Here’s a look at the key stages:

1.Uncoiling & Straightening:

2.Pre-Notching (Optional):

3.The Forming Mill:

4.High-Frequency (HF) Welding:

5.Sizing & Calibration:

6.Cutting to Length:

7.Output & Collection:

Key Advantages of Using a Tube Forming Machine

High Efficiency & Speed: Produce tubes continuously at speeds of 10 to 100+ meters per minute, dramatically increasing output.

Superior Consistency: Every tube produced is identical in dimension and shape, eliminating human error and ensuring product quality.

Material & Cost Savings: Buying metal in coil form is more cost-effective than pre-formed sheets. The automated process also reduces labor costs.

Incredible Flexibility: With quick tooling changes, a single machine can produce a wide range of tube sizes and wall thicknesses, allowing you to respond quickly to market demands.

Exceptional Weld Quality: HF welding creates a strong, ductile weld seam that is often as strong as, or stronger than, the parent metal itself.

Applications: Where Are These Tubes Used?

The tubes produced by these machines are everywhere:

Construction: Building frames, roof trusses, and support structures.

Furniture: Modern tables, chairs, shelves, and bed frames.

Automotive & Transportation: Chassis components, trailer frames, and roll cages.

Industrial Equipment: Machine guards, conveyor systems, and storage racks.

Recently Posted

-

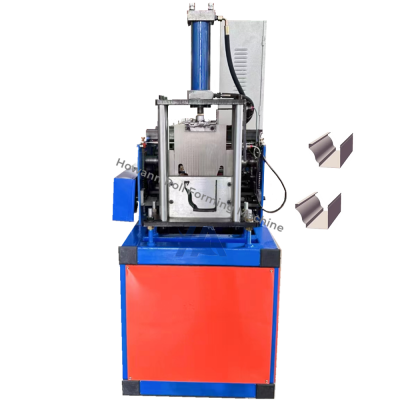

V-shape stud channel roll forming machine

November 7, 2025The V-Type Purlin Forming Machine: Engine for Efficient Steel Structure ManufacturingIn the world of modern construction and pre-e Read More

Read More -

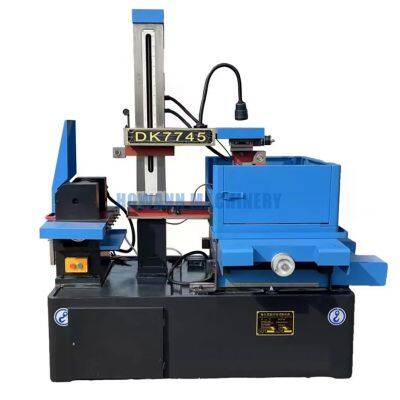

steel pipe roll forming machine

October 16, 2025Shaping the World: The Power of the Modern Metal Tube Forming MachineFrom the sleek handrails in your home to the complex structur Read More

Read More -

The Power to Produce Beauty. Elevate Your Roofing Supply with Our Forming Machine.

October 11, 2025Single-Ply Metal Glazed Tile Forming MachineOur Single-Ply Metal Glazed Tile Forming Machine is an advanced roll-forming system de Read More

Read More