steel pipe roll forming machine

Shaping the World: The Power of the Modern Metal Tube Forming Machine

From the sleek handrails in your home to the complex structural components in aerospace and automotive industries, metal tubes are a fundamental part of our modern world. But how are these versatile, high-strength components created? The answer lies at the heart of advanced manufacturing: the Metal Tube Forming Machine.

This technology has evolved far beyond simple pipe bending. Today's tube forming machinery represents a blend of precision engineering, automation, and robust design, enabling manufacturers to achieve unprecedented levels of quality, efficiency, and complexity.

The Core Process: From Coil to Tube

At its essence, a metal tube forming line transforms raw material—typically a steel or aluminum coil—into a finished, high-integrity tube through a continuous, automated process. The key stages often include:

Uncoiling & Leveling: The metal coil is loaded and carefully straightened to ensure a flawless starting point.

Forming: The heart of the machine. A series of precision-engraved rollers progressively shape the flat strip into a circular profile. This is a masterful display of mechanical engineering, where the metal is formed without material removal.

Welding: For welded tubes, the open edges are fused together. High-Frequency (HF) Welding is the gold standard, creating a strong, clean seam at high speeds.

Sizing: The newly welded tube passes through another set of rolls to calibrate its final diameter and achieve perfect roundness.

Cutting & Handling: The continuous tube is cut to precise lengths using flying cutoffs and is then automatically stacked or packaged.

Key Advantages of Advanced Tube Forming Technology

Why are these machines so critical to modern production?

Unmatched Precision & Consistency: Modern CNC-controlled systems ensure that every meter of tube produced meets exact dimensional tolerances, batch after batch. This reliability is non-negotiable in industries like automotive and construction.

High-Speed Production: Automated lines can run 24/7, transforming raw coil into finished product at remarkable speeds, dramatically boosting output and reducing lead times.

Incredible Versatility: By simply changing the roll tooling and adjusting parameters, a single mill can produce a wide range of tube diameters, wall thicknesses, and even custom shapes like square or rectangular sections.

Superior Strength & Quality: The cold-forming process work-hardens the metal, enhancing its strength. Combined with advanced welding techniques, the resulting tubes are capable of withstanding extreme pressures and loads.

Applications Across Industries

The versatility of tube forming machines means their impact is felt everywhere:

Automotive: Exhaust systems, chassis components, roll cages, and hydraulic lines.

Construction: Structural sections, scaffolding, handrails, and furniture frames.

HVAC: Ductwork, heat exchanger tubes, and refrigerant lines.

Aerospace & Defense: Lightweight structural members and fluid-carrying systems.

Choosing the Right Partner

Investing in a metal tube forming machine is a significant decision. The right manufacturer will offer more than just a machine; they will provide a complete production solution. Look for a partner that emphasizes robust construction, user-friendly CNC controls, comprehensive after-sales support, and the ability to customize the line to your specific material and output needs.

We are dedicated to pushing the boundaries of tube forming technology. Our machines are engineered for durability, precision, and seamless integration into your smart factory.

Ready to shape your future in metal? Contact us today to discover how our tube forming solutions can elevate your production capabilities.

Recently Posted

-

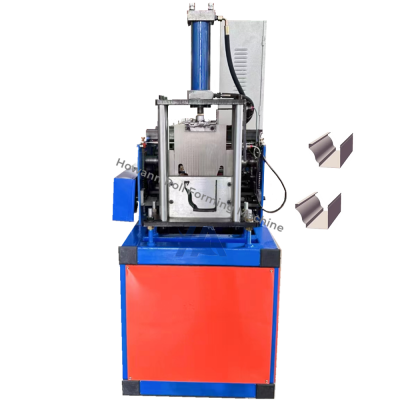

V-shape stud channel roll forming machine

November 7, 2025The V-Type Purlin Forming Machine: Engine for Efficient Steel Structure ManufacturingIn the world of modern construction and pre-e Read More

Read More -

Boost Your Output, Squarely.

October 29, 2025The Ultimate Guide to Welding Square Tube Forming MachinesIn the world of metal fabrication and construction, square and rectangul Read More

Read More -

The Power to Produce Beauty. Elevate Your Roofing Supply with Our Forming Machine.

October 11, 2025Single-Ply Metal Glazed Tile Forming MachineOur Single-Ply Metal Glazed Tile Forming Machine is an advanced roll-forming system de Read More

Read More